Hammerhead: AV Sensor Unit

Product Designer

Project Summary

Hammerhead is an AV perception sensor casing system that is easy to service, manufacture, and distribute across different vehicle models.

Applied Skills

Technology Literature Review, Product Design, Fusion 360

The autonomous vehicle (AV) division of Ridecell (Auro) is developing AV technology for rebalancing and delivery of rental cars. Working with the Auro engineering team, I designed a sensor casing system that is easy to service, manufacture, and distribute across different vehicle models.

Autonomy for carsharing and truck rentals

Customers of carsharing and truck rental services often end their rentals at locations that are not optimal for the next customer, e.g. their homes. The vehicles also need to be refueled and recharged on a regular basis. Instead of dispatching service workers to complete all of these tasks, Auro is developing autonomous technology that will relocate the vehicles back to their stations for servicing. The technology will then bring the vehicles back out on the streets at high demand locations. The AI powered driver will also serve as an artificial valet, able to deliver the vehicle directly to the renter’s doorstep.

In order to enable such autonomy use cases, the Auro team developed a sensor system that perceives the environment around the AV. The perception data will allow the vehicle to navigate safely around city streets without human supervision. During 2020, I joined the design and engineering team to develop concepts and a prototype for the sensor system’s casing.

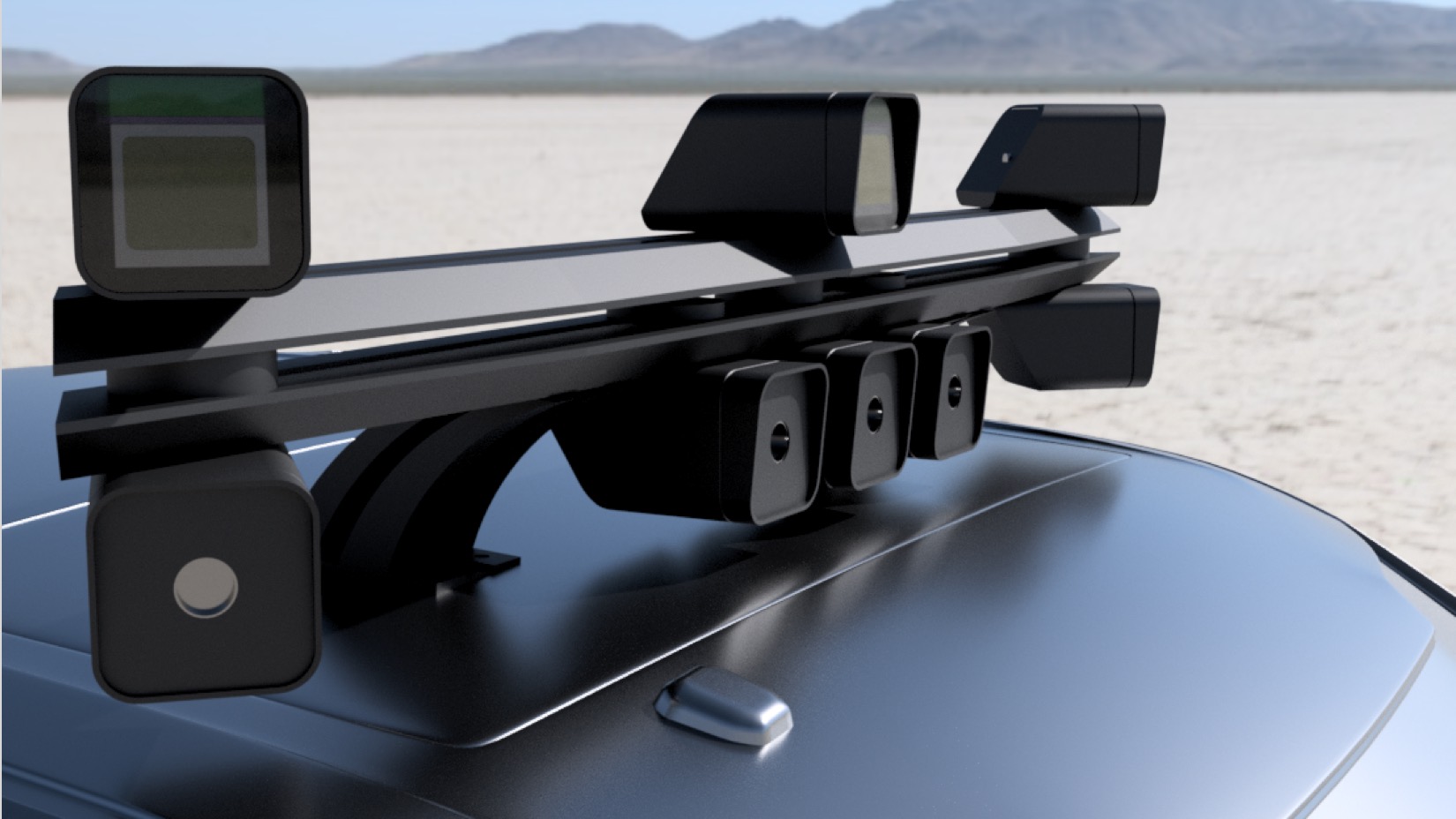

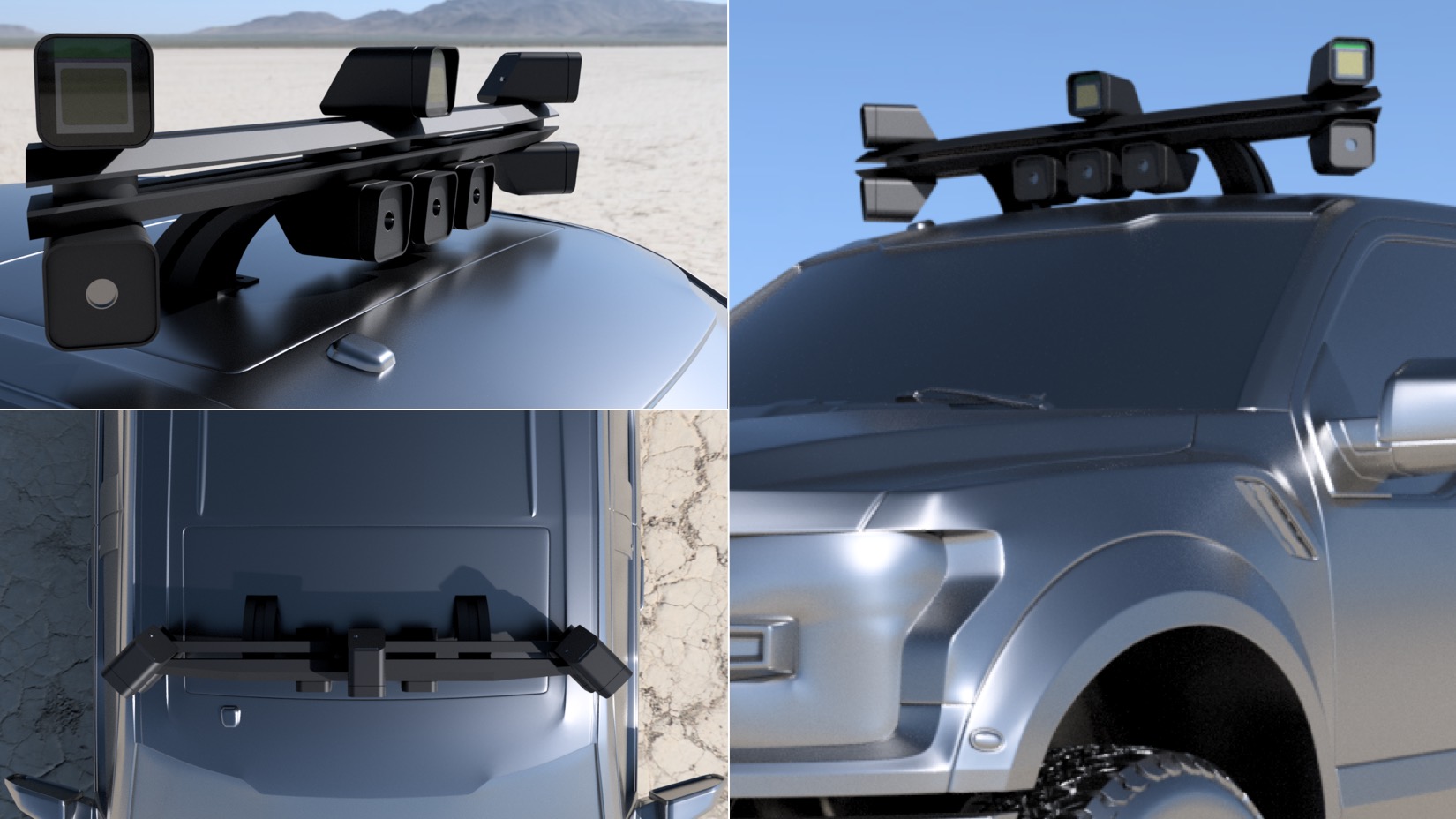

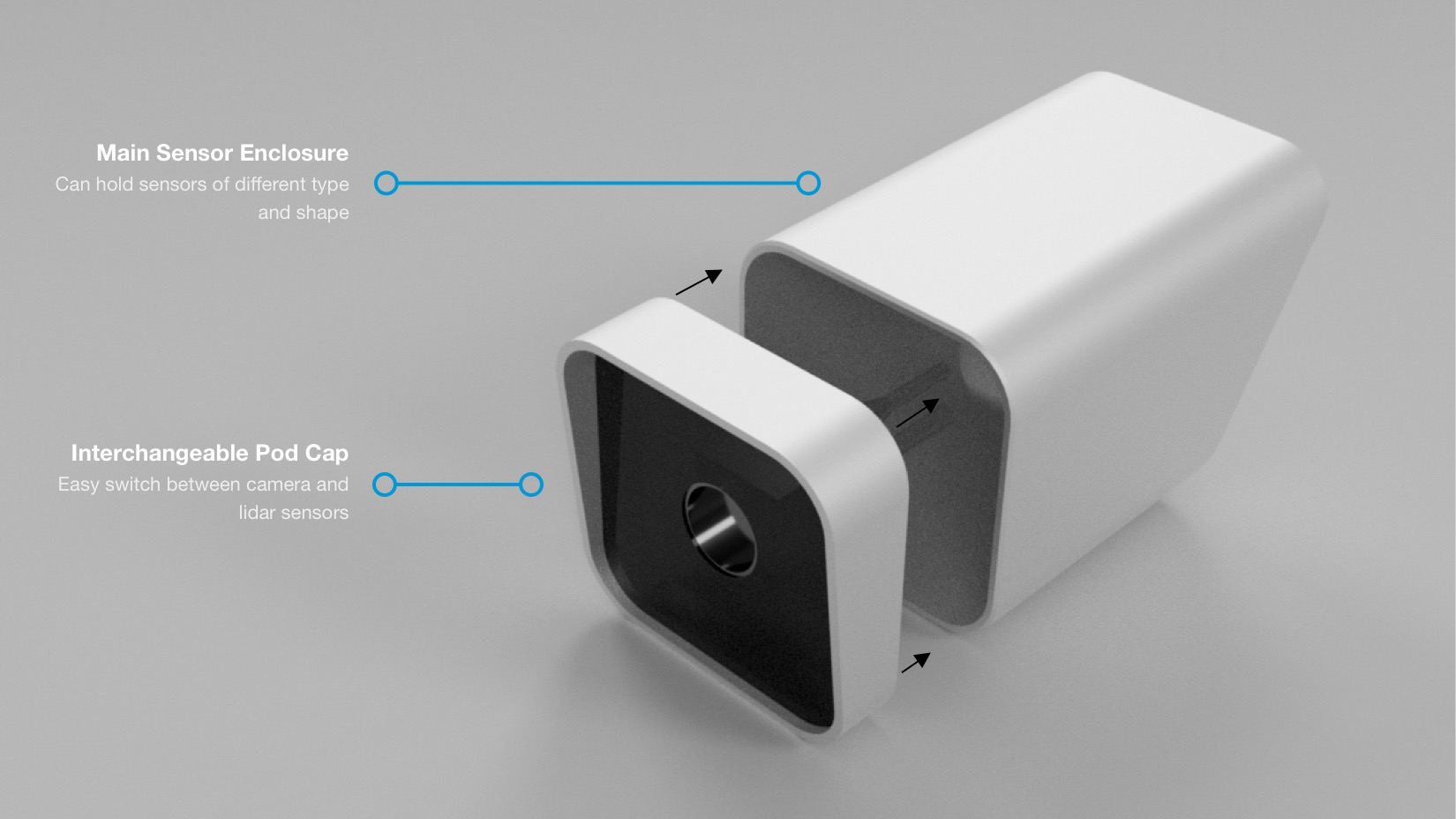

Sensor unit anatomy

The sensor unit had to be vehicle agnostic, i.e. fit and operate on a variety of models. The unit also had to allow for easy repairs and replacements of sensor devices (lidars and cameras). In order to minimize costs, the perception system was developed with off-the-shelf sensors. The project also called for a reduction in the manufacturing costs associated with the housing unit.

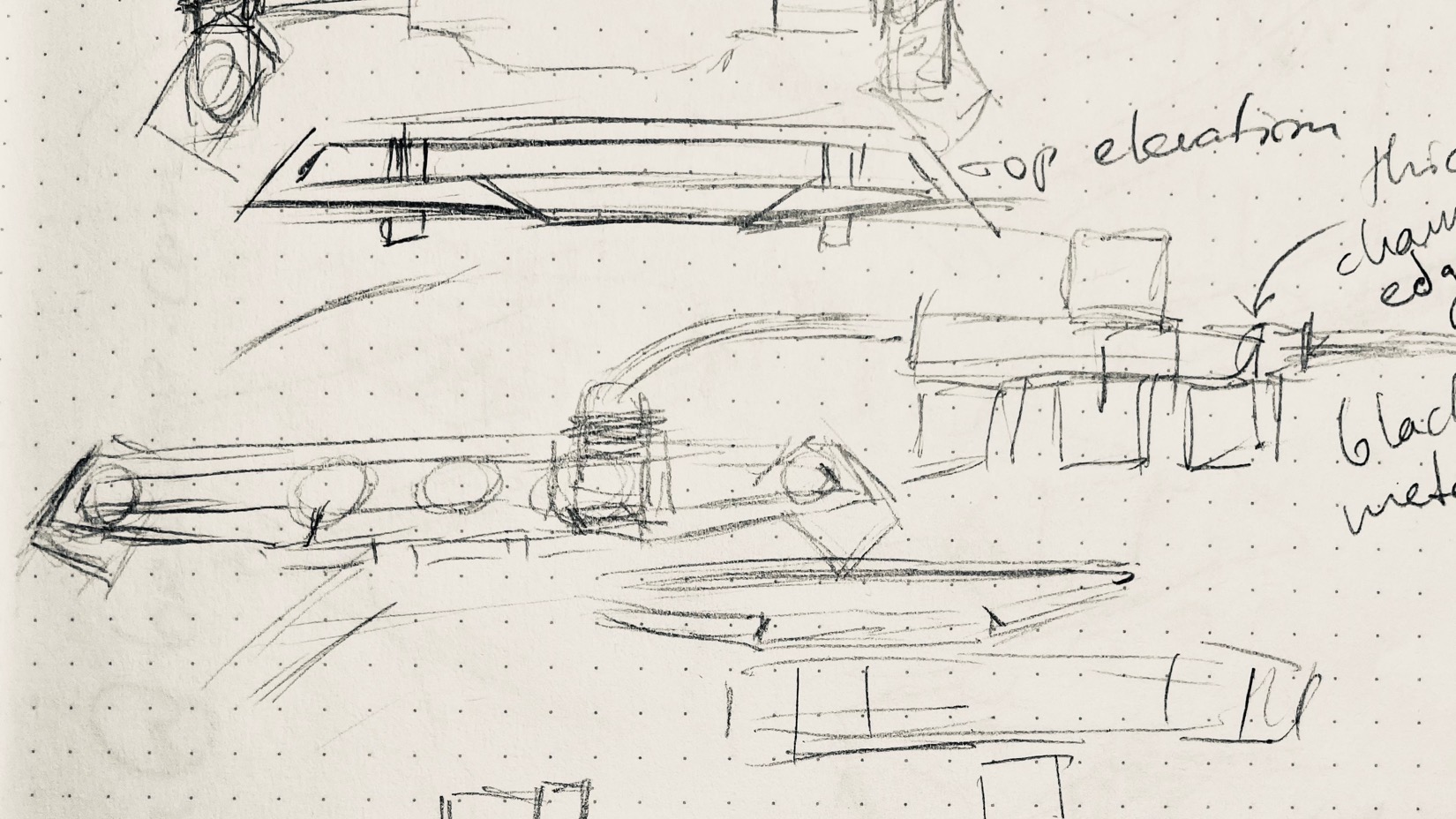

The team and I decided to focus on a modular approach. In my concept, I created modular pods with interchangeable caps to allow for the housing of different sensor types. The pods can house off-the-shelf sensors without the need of customization. The pods are modules of the same size and shape which makes them easily replicable in a manufacturing process, thus making the overall system cheaper to produce at scale.

In order to mount the pod modules on the vehicle, I designed a rail base. The rail base allows the pods to be easily disassembled and assembled again for servicing or adjustments. The rail base can also be mounted on the roof of any vehicle, making it vehicle agnostic.